Understanding the Manufacturing Process of Custom Membrane Switches

Understanding the Manufacturing Process of Custom Membrane Switches

Blog Article

Membrane Layer Switch Over Innovation: The Trick to Reputable and Cost-efficient User Interfaces

Membrane button technology has actually emerged as a critical component in the layout of customer interfaces, providing both integrity and cost-effectiveness throughout a varied variety of applications. As we check out the multifaceted benefits of membrane layer switches, their possibility for advancement raises inquiries regarding future applications and developing trends.

Recognizing Membrane Switch Modern Technology

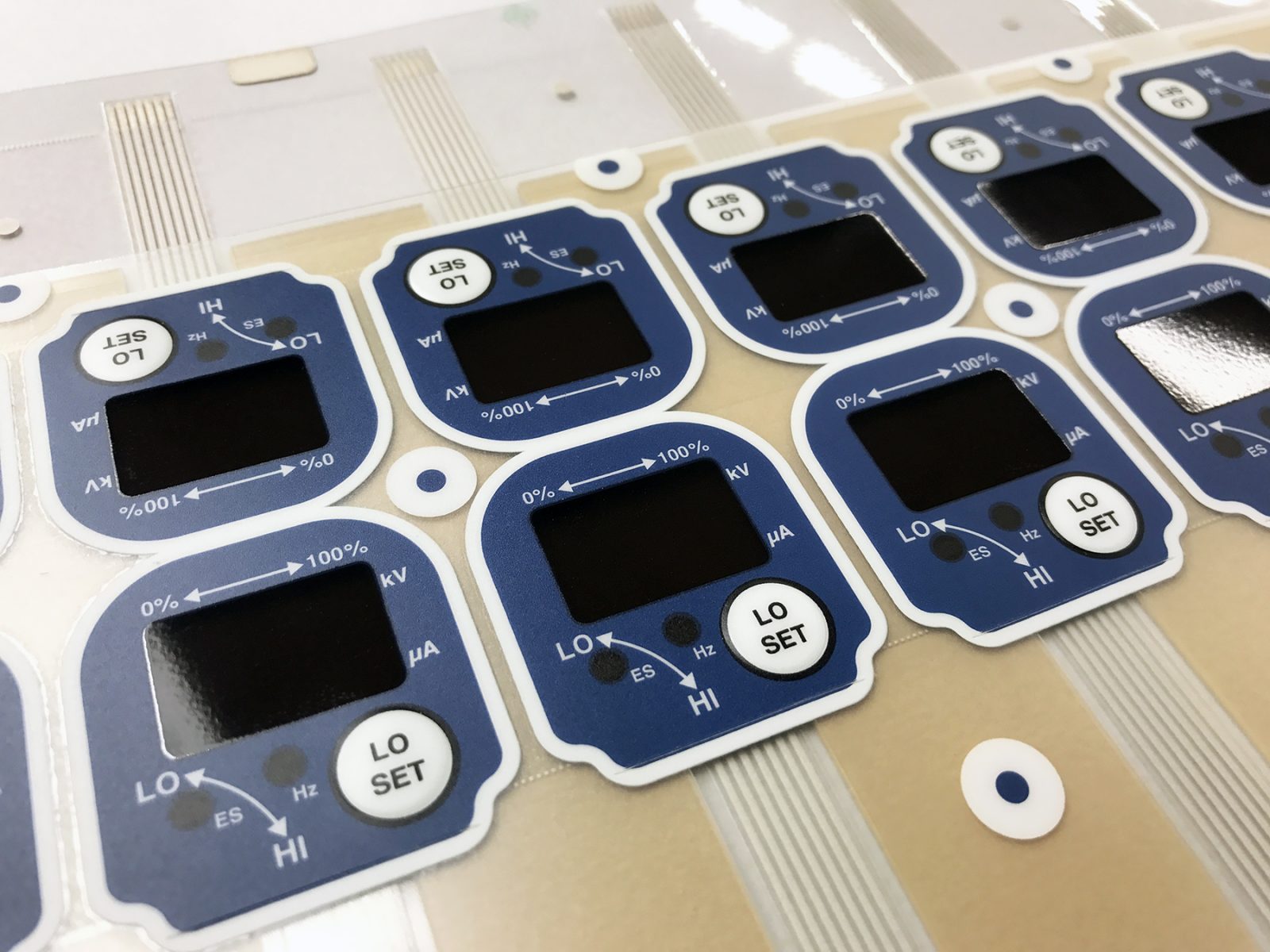

Membrane layer switch technology is an extensively used interface solution in numerous digital gadgets, offering a smooth blend of functionality and layout. This innovation integrates several layers of products, typically consisting of a graphic overlay, spacer layer, and a circuit layer. The graphic overlay displays the interface elements, while the spacer layer divides the circuit layer from the overlay till a user triggers a button.

When stress is related to the overlay, the circuit layer finishes the electric circuit, sending out a signal to the gadget. This system permits various setups, consisting of responsive responses and backlighting options, enhancing customer interaction. Membrane switches are commonly manufactured using sturdy products such as polyester or polycarbonate, ensuring long life and resistance to ecological variables like moisture and dust.

The adaptability of membrane layer switches allows their application in diverse sectors, including medical gadgets, consumer electronic devices, and industrial controls. Their small style enables combination right into space-constrained settings, offering an efficient interface without jeopardizing aesthetic appeal. Understanding the complexities of membrane layer switch modern technology is necessary for suppliers and developers looking for to develop dependable and effective human-machine interfaces.

Key Benefits of Membrane Layer Buttons

While numerous user interface remedies exist, membrane layer switches over deal distinctive benefits that make them a recommended selection in various applications. Among the key advantages is their longevity; membrane buttons are designed to hold up against extreme environmental problems, including dampness, dirt, and temperature changes, ensuring durable efficiency. This resilience substantially reduces the requirement for constant substitutes, thus reducing total maintenance prices.

Moreover, membrane layer switches are light-weight and small, making them ideal for applications where area is restricted. Their inconspicuous style contributes to a smooth appearance without compromising capability.

Cost-effectiveness is additionally a remarkable advantage, as the production procedure for membrane switches over has a tendency to be more economical contrasted to typical mechanical buttons. This cost, combined with their reliability and simplicity of installation, placements membrane switches as a practical solution for a wide variety of sectors looking for effective and effective user interfaces.

Applications Throughout Various Industries

Just how do membrane layer buttons adjust to the varied needs of numerous sectors? Membrane layer button technology is significantly recognized for its versatility, making it appropriate for a broad range of applications throughout multiple markets. In the medical field, membrane switches are used in analysis equipment and individual surveillance gadgets, where their durability and ease of cleaning are important for maintaining hygiene standards. The automotive industry employs these buttons in dashboards and control board, using a streamlined visual while making sure easy to use operation.

In consumer electronics, membrane buttons supply a small solution for push-button controls and home appliances, improving user experience through intuitive layout. In addition, the industrial market leverages membrane buttons for equipment control panels, taking advantage of their resistance to severe environments, such as dampness and dust.

Armed forces and aerospace applications also use membrane buttons for their dependability and ability to hold up against severe conditions, making certain functional effectiveness in crucial scenarios. Additionally, the food and drink market embraces these buttons for automated systems, where cleanliness and ease of procedure are extremely important. Eventually, membrane layer switches are customized to satisfy the distinct needs of each sector, verifying their crucial role in modern technology user interfaces

Design and Customization Options

In the world of membrane visit switch technology, layout and customization options play a pivotal role in improving performance and user interaction. These buttons can be tailored to fulfill particular functional needs and visual choices, making them versatile elements in various applications.

Among the primary personalization alternatives is the design of pop over to this web-site the button itself, which can be made to suit special user interfaces and ergonomic factors to consider. By readjusting the shape, dimension, and arrangement of buttons, producers can create user-friendly layouts that help with convenience of use. In addition, the unification of various shades and visuals overlays enables branding and improved visibility, making certain that customers can swiftly recognize functions.

Moreover, membrane layer switches can be crafted with different responsive responses devices, such as raised switches or distinct clicks, to boost the customer experience. Different products can additionally be picked for longevity and ecological resistance, addressing variables such as moisture, temperature level fluctuations, and chemical exposure.

Inevitably, the comprehensive layout and modification options offered in membrane layer button modern technology equip companies to develop customized options that not just satisfy practical needs but additionally align with their branding and operational needs.

Future Patterns in Membrane Switches

As membrane layer button modern technology remains to advance, future trends are significantly Learn More Here concentrated on improving individual experience and incorporating advanced capabilities. One substantial trend is the assimilation of touch-sensitive and capacitive innovations into conventional membrane switches. This growth permits even more instinctive individual interfaces, providing tactile responses while preserving a streamlined design.

One more arising pattern is the usage of eco friendly products, driven by the growing demand for lasting production methods. Makers are looking for to decrease their carbon impact by using recyclable substratums and low-impact inks, aligning with international sustainability objectives.

Additionally, the surge of the Web of Things (IoT) is motivating the incorporation of wise attributes right into membrane layer switches. Boosted connection alternatives will enable devices to interact with each other, enabling seamless combination right into broader systems.

Furthermore, innovations in printing innovations, such as digital printing, are enabling higher layout adaptability and modification. This enables suppliers to produce complex layouts and vibrant colors cost-effectively.

Conclusion

In conclusion, membrane layer switch technology represents an important innovation in individual interface style, offering significant benefits in toughness, personalization, and cost-effectiveness. As developments continue to arise, especially in touch-sensitive user interfaces and lasting products, the potential for membrane layer changes to improve customer experience and functionality continues to be appealing.

Report this page